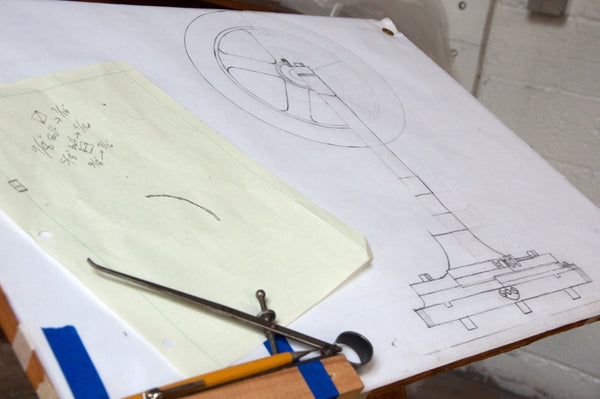

Recently, I spent most of a week at Hamilton Wood Type & Printing Museum drawing a machine. An industrial manufacturing machine with a cast iron body and pair of heavy machined flywheels. When it was in active use in the Hamilton Manufacturing Co. factory, it was motivated by means of an overhead driveshaft, a leather belt, and a wooden three-speed pulley.

The machine was used to make decorative wood type border pieces for embellishing posters and other large printed materials. In contrast to wood type letters, which Hamilton’s type cutters rendered in blocks of end-grain rock maple using air-driven, pantograph-mounted routers, wood type border was made using this machine — a reciprocating die press which impressed patterns into end-grain wood, leaving the printing surface in relief.

The Hamilton Museum is fortunate that there are former Hamilton Manufacturing Co. employees still living who can share their firsthand knowledge of the type cutting process. The die-stamping machine saw some limited use in Hamilton’s later years for adding details to a few particularly ornate typefaces, but the days of its regular use for its original purpose have faded out of memory.

Making drawings of the machine serves two purposes. First, the pen-and-ink drawings I will make from the measured pencil drawings will illustrate my master’s thesis. Second, and more importantly, drawing the machine helped me apprehend it more completely. The drawing was a kind of disciplined attention, requiring me to measure and render aspects of the machine that might otherwise have escaped notice.

The master’s degree I am working toward is in Industrial Archaeology, a discipline which bears some definition. One of my professors at Michigan Tech, Dr. Timothy Scarlett, described it succinctly in a conversation we had shortly before I left for Two Rivers: “Industrial Archaeologists study the physical residues of industrial societies.” The word “residues” was carefully chosen — broad enough to cover industrialization’s wide-ranging legacies. In the western Upper Peninsula of Michigan, where I live and study, the residues of industry include the ruins of copper mining works, as well as the fields of waste tailings and piles of poor rock that are equally a part of the post-mining landscape.

In the case of my research into the wood type border stamping machine, the subject of study is less tangible. It has to do with work itself and with knowledge rooted in the tactile experience of operating this machine — knowledge intrinsically shaped by the industrialization of manufacturing.

From initial observations of the die stamping machine — rotating its flywheel and watching its movements — it is clear that operating it successfully required an innate sensitivity to the machine’s cadence. It must also have required a working knowledge of the printers’ measurement system, an ability to make precise adjustments to the machine, and a capacity to tolerate working with a machine whose designers made few if any ergonomic allowances. By operating the machine in a structured and controlled experiment, I hope to generate some data that will effectively characterize that knowledge and experience.

I hope to complete the experiment’s design by late December, and begin conducting it in early January. In the meantime, I am looking forward to spending more time drawing the machine during the first week of November and attending Wayzgoose!