By Jim Moran

Nearly every poster in the Dry Goods Store at the Hamilton Wood Type & Printing Museum comes from the museum's Collection. How exactly do they get there?

Blocks are chosen as a way of recording what’s in the collection while creating new work to sell. A series of hand-carved blocks from storage get removed carefully from a crate and cleaned.

From there, they move to the photography station to be added to our image archive. A four-color poster has four blocks which are photographed individually and as a group.

Next, a determination of the order of printing is considered. In preparation for printing, the blocks are rubbed with mineral oil to condition and strengthen them for standing up to the pressure of the press.

When we move on to printing, each color must be printed alone to make a distinct separation as a record of that block. Notes are taken regarding everything from the physical condition of each block to how well each block aligns or registers to the others.

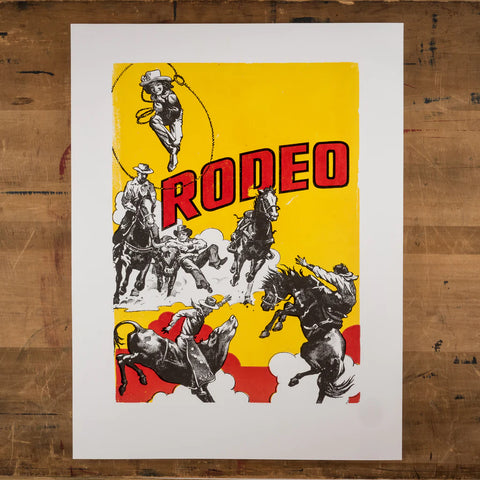

The print edition size depends on condition of the blocks, how “sellable” the final prints may be, and the relative difficulty of the printing process. A typical poster run is between 30 and 50 prints, but again, if one block cracks or the wood seems weak, the run could be limited to ten prints. In a perfect world, the colors align, the blocks are strong, and 50 new posters move on to Dry Goods in hopes of finding new homes with appreciative buyers.